The Role of Monitoring Solutions in Ensuring Semiconductor Production Quality

- AAAPlus Automation

- Jun 12, 2024

- 2 min read

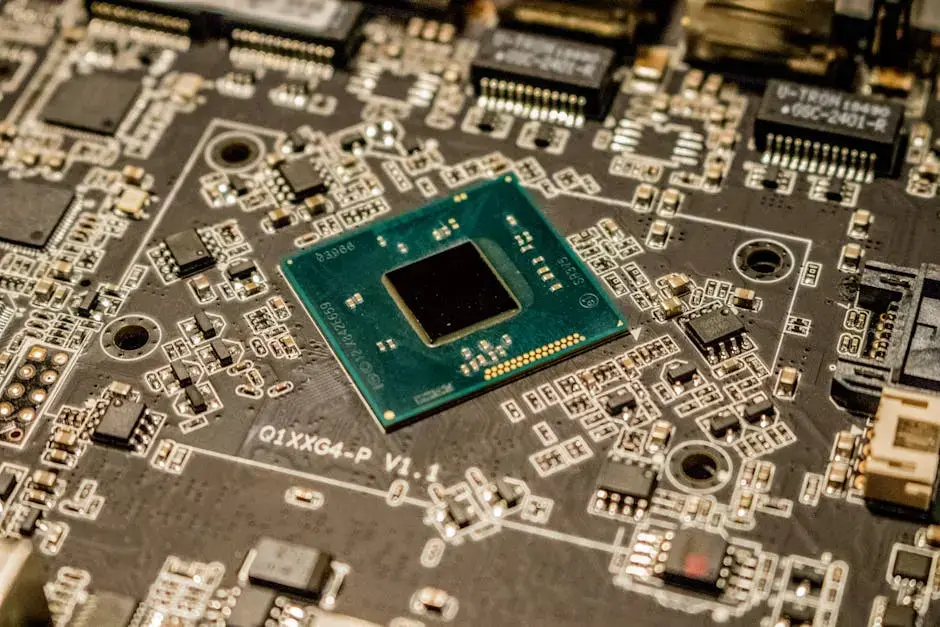

In the intricate world of semiconductor production, the pivotal role of monitoring solutions cannot be overstated. These cutting-edge tools act as the vigilant guardians, ensuring that each tiny chip meets the highest standards of quality before it powers the next technological breakthrough. Dive into the realm where precision meets technology, and reliability is not just a buzzword but a way of life in semiconductor manufacturing.

The Importance of Monitoring Solutions in Semiconductor Manufacturing

Imagine a bustling semiconductor production floor, where the tiniest imperfection can lead to colossal consequences. This is where monitoring solutions step in as the silent sentinels, meticulously observing and analyzing every step of the manufacturing process. From monitoring temperature variations to detecting minute deviations, these solutions ensure that each chip meets rigorous quality standards.

In an industry where precision is paramount, monitoring solutions offer real-time insights that enable swift corrective actions. By catching anomalies before they evolve into issues, these tools play a crucial role in safeguarding the integrity of semiconductor production. With the ability to detect defects at their inception, manufacturers can maintain the quality that defines their reputation.

Moreover, monitoring solutions play a vital role in optimizing production efficiency. By providing data-driven feedback, these tools enable manufacturers to fine-tune their processes, minimize waste, and enhance overall productivity. The seamless integration of monitoring solutions into the manufacturing workflow not only ensures quality assurance but also drives operational excellence.

Utilizing Advanced Technology for Quality Assurance

As semiconductor production processes become increasingly complex, the demand for advanced monitoring solutions continues to rise. These sophisticated tools leverage cutting-edge technologies such as artificial intelligence and machine learning to analyze vast amounts of data with unparalleled speed and accuracy.

The marriage of technology and quality assurance has never been more critical than in the semiconductor industry. Monitoring solutions equipped with AI capabilities can predict potential defects, preemptively identify issues, and optimize processes for peak performance. This proactive approach not only ensures the production of flawless chips but also drives innovation in semiconductor manufacturing.

In the fast-paced world of semiconductor production, staying ahead of the curve is essential. By embracing state-of-the-art monitoring solutions, manufacturers can navigate the intricacies of modern chip fabrication with confidence. These advanced tools empower industry professionals to uphold the highest standards of quality and precision, paving the way for groundbreaking advancements in technology.

As technology advances at a rapid pace, the reliance on monitoring solutions will only grow stronger. Embracing these tools is key to not only meeting but exceeding the quality expectations in semiconductor production. Let the watchful eyes of these solutions guide the way to a future where flawless chips power the innovations of tomorrow.

Comments